泊头市友盛联轴器有限公司是从事联轴器、减速机及支架的研究的企业。我公司各种设备多样,产品主要有:梅花形弹性联轴器,鼓形齿式联轴器,弹性套柱销联轴器,弹性柱销联轴器,弹性柱销齿式联轴器,星形弹性联轴器等。详细

泊头市友盛联轴器有限公司是从事联轴器、减速机及支架的研究的企业。我公司各种设备多样,产品主要有:梅花形弹性联轴器,鼓形齿式联轴器,弹性套柱销联轴器,弹性柱销联轴器,弹性柱销齿式联轴器,星形弹性联轴器等。详细

| 地址: | 泊头市小杜庄工业园 |

| 网址: | www.btwdlzq.com |

| 邮箱: | 2690587660@qq.com |

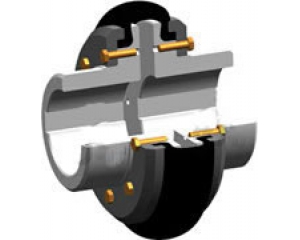

GB5844-89轮胎联轴器

GB5844-89轮胎联轴器适用于连接两同心轴的传动轴系;具有补偿两轴相对偏移和良好的减振、缓冲、电绝缘性能、不需润滑,装拆方便,工作温度为-20~+80℃;有圆柱形或圆锥形轴孔,可用于潮湿、多尘、有冲击、振动、正反转和起动频繁的工作条件。本标准联轴器,我公司已批量生产。质量、,为满足各种机械产品的 新改造和引进设备备件需要,我公司可按 标准提供品种和的梅花型弹性联轴器。

泊头市友盛联轴器有限公司, 供应国标件UL型轮胎联轴器,具体参数见下表:

|

43型号

|

允许转矩

Tn N·m |

瞬时

大 转矩 |

许用

转速 [n] r/min |

轴孔直径

|

轴孔长度

|

D

|

B

|

质量

Kg |

转动惯量I

/kg·m2 |

|

|

J,J1

|

Y

|

|||||||||

|

d

|

L

|

|||||||||

|

UL1

|

10

|

31.5

|

5000

|

11-18

|

22-30

|

25-42

|

80

|

20

|

0.7

|

0.0003

|

|

UL2

|

25

|

80

|

5000

|

14-22

|

27-38

|

32-52

|

100

|

26

|

1.2

|

0.0008

|

|

UL3

|

63

|

180

|

4500

|

18-25

|

30-44

|

42-62

|

120

|

32

|

1.8

|

0.0022

|

|

UL4

|

100

|

315

|

4300

|

20-30

|

38-60

|

52-82

|

140

|

38

|

3.0

|

0.0044

|

|

UL5

|

160

|

500

|

4000

|

24-35

|

38-60

|

52-82

|

160

|

45

|

4.6

|

0.0084

|

|

UL6

|

250

|

710

|

3600

|

28-40

|

44-84

|

62-112

|

180

|

50

|

7.1

|

0.0164

|

|

UL7

|

315

|

900

|

3200

|

32-48

|

60-84

|

82-112

|

200

|

56

|

10.9

|

0.0290

|

|

UL8

|

400

|

1250

|

3000

|

38-50

|

60-84

|

82-112

|

220

|

63

|

13.0

|

0.0448

|

|

UL9

|

630

|

1800

|

2800

|

42-60

|

84-107

|

112-142

|

250

|

71

|

20.0

|

0.0898

|

|

UL10

|

800

|

2240

|

2400

|

45-70

|

84-107

|

112-142

|

280

|

80

|

30.6

|

0.1596

|

|

UL11

|

1000

|

2500

|

2100

|

50-75

|

84-107

|

112-142

|

320

|

90

|

39

|

0.2792

|

|

UL12

|

1600

|

4000

|

2000

|

55-85

|

84-132

|

112-172

|

360

|

100

|

59

|

0.5356

|

|

UL13

|

2500

|

6300

|

1800

|

63-95

|

107-132

|

142-172

|

400

|

110

|

81

|

0.8960

|

|

UL14

|

4000

|

10000

|

1600

|

75-110

|

107-167

|

142-212

|

480

|

130

|

145

|

2.2616

|

|

UL15

|

6300

|

14000

|

1200

|

85-125

|

132-167

|

172-212

|

560

|

150

|

222

|

4.6456

|

|

UL16

|

10000

|

20000

|

1000

|

100-140

|

167-202

|

212-252

|

630

|

180

|

302

|

8.0924

|

|

UL17

|

16000

|

31500

|

900

|

120-160

|

167-242

|

212-302

|

750

|

210

|

561

|

20.0176

|

|

UL18

|

25000

|

59000

|

800

|

140-180

|

202-242

|

252-302

|

900

|

250

|

818

|

43.0530

|

|

43型号

|

允许转矩

Tn N·m |

瞬时

大 转矩 |

许用

转速 [n] r/min |

轴孔直径

|

轴孔长度

|

D

|

B

|

质量

Kg |

转动惯量I

/kg·m2 |

|

|

J,J1

|

Y

|

|||||||||

|

d

|

L

|

|||||||||

|

UL1

|

10

|

31.5

|

5000

|

11-18

|

22-30

|

25-42

|

80

|

20

|

0.7

|

0.0003

|

|

UL2

|

25

|

80

|

5000

|

14-22

|

27-38

|

32-52

|

100

|

26

|

1.2

|

0.0008

|

|

UL3

|

63

|

180

|

4500

|

18-25

|

30-44

|

42-62

|

120

|

32

|

1.8

|

0.0022

|

|

UL4

|

100

|

315

|

4300

|

20-30

|

38-60

|

52-82

|

140

|

38

|

3.0

|

0.0044

|

|

UL5

|

160

|

500

|

4000

|

24-35

|

38-60

|

52-82

|

160

|

45

|

4.6

|

0.0084

|

|

UL6

|

250

|

710

|

3600

|

28-40

|

44-84

|

62-112

|

180

|

50

|

7.1

|

0.0164

|

|

UL7

|

315

|

900

|

3200

|

32-48

|

60-84

|

82-112

|

200

|

56

|

10.9

|

0.0290

|

|

UL8

|

400

|

1250

|

3000

|

38-50

|

60-84

|

82-112

|

220

|

63

|

13.0

|

0.0448

|

|

UL9

|

630

|

1800

|

2800

|

42-60

|

84-107

|

112-142

|

250

|

71

|

20.0

|

0.0898

|

|

UL10

|

800

|

2240

|

2400

|

45-70

|

84-107

|

112-142

|

280

|

80

|

30.6

|

0.1596

|

|

UL11

|

1000

|

2500

|

2100

|

50-75

|

84-107

|

112-142

|

320

|

90

|

39

|

0.2792

|

|

UL12

|

1600

|

4000

|

2000

|

55-85

|

84-132

|

112-172

|

360

|

100

|

59

|

0.5356

|

|

UL13

|

2500

|

6300

|

1800

|

63-95

|

107-132

|

142-172

|

400

|

110

|

81

|

0.8960

|

|

UL14

|

4000

|

10000

|

1600

|

75-110

|

107-167

|

142-212

|

480

|

130

|

145

|

2.2616

|

|

UL15

|

6300

|

14000

|

1200

|

85-125

|

132-167

|

172-212

|

560

|

150

|

222

|

4.6456

|

|

UL16

|

10000

|

20000

|

1000

|

100-140

|

167-202

|

212-252

|

630

|

180

|

302

|

8.0924

|

|

UL17

|

16000

|

31500

|

900

|

120-160

|

167-242

|

212-302

|

750

|

210

|

561

|

20.0176

|

|

UL18

|

25000

|

59000

|

800

|

140-180

|

202-242

|

252-302

|

900

|

250

|

818

|

43.0530

|

| UL型轮胎联轴器 | http://www.btwdlzq.com/ltslzq/61.html |

| LA型轮胎联轴器 | http://www.btwdlzq.com/ltslzq/60.html |

| 轮胎联轴器 | http://www.btwdlzq.com/ltslzq/ |

|

43型号

|

允许转矩

Tn N·m |

瞬时

大 转矩 |

许用

转速 [n] r/min |

轴孔直径

|

轴孔长度

|

D

|

B

|

质量

Kg |

转动惯量I

/kg·m2 |

|

|

J,J1

|

Y

|

|||||||||

|

d

|

L

|

|||||||||

|

UL1

|

10

|

31.5

|

5000

|

11-18

|

22-30

|

25-42

|

80

|

20

|

0.7

|

0.0003

|

|

UL2

|

25

|

80

|

5000

|

14-22

|

27-38

|

32-52

|

100

|

26

|

1.2

|

0.0008

|

|

UL3

|

63

|

180

|

4500

|

18-25

|

30-44

|

42-62

|

120

|

32

|

1.8

|

0.0022

|

|

UL4

|

100

|

315

|

4300

|

20-30

|

38-60

|

52-82

|

140

|

38

|

3.0

|

0.0044

|

|

UL5

|

160

|

500

|

4000

|

24-35

|

38-60

|

52-82

|

160

|

45

|

4.6

|

0.0084

|

|

UL6

|

250

|

710

|

3600

|

28-40

|

44-84

|

62-112

|

180

|

50

|

7.1

|

0.0164

|

|

UL7

|

315

|

900

|

3200

|

32-48

|

60-84

|

82-112

|

200

|

56

|

10.9

|

0.0290

|

|

UL8

|

400

|

1250

|

3000

|

38-50

|

60-84

|

82-112

|

220

|

63

|

13.0

|

0.0448

|

|

UL9

|

630

|

1800

|

2800

|

42-60

|

84-107

|

112-142

|

250

|

71

|

20.0

|

0.0898

|

|

UL10

|

800

|

2240

|

2400

|

45-70

|

84-107

|

112-142

|

280

|

80

|

30.6

|

0.1596

|

|

UL11

|

1000

|

2500

|

2100

|

50-75

|

84-107

|

112-142

|

320

|

90

|

39

|

0.2792

|

|

UL12

|

1600

|

4000

|

2000

|

55-85

|

84-132

|

112-172

|

360

|

100

|

59

|

0.5356

|

|

UL13

|

2500

|

6300

|

1800

|

63-95

|

107-132

|

142-172

|

400

|

110

|

81

|

0.8960

|

|

UL14

|

4000

|

10000

|

1600

|

75-110

|

107-167

|

142-212

|

480

|

130

|

145

|

2.2616

|

|

UL15

|

6300

|

14000

|

1200

|

85-125

|

132-167

|

172-212

|

560

|

150

|

222

|

4.6456

|

|

UL16

|

10000

|

20000

|

1000

|

100-140

|

167-202

|

212-252

|

630

|

180

|

302

|

8.0924

|

|

UL17

|

16000

|

31500

|

900

|

120-160

|

167-242

|

212-302

|

750

|

210

|

561

|

20.0176

|

|

UL18

|

25000

|

59000

|

800

|

140-180

|

202-242

|

252-302

|

900

|

250

|

818

|

43.0530

|